Types of Electric Scooter Motors

Diverse Varieties of Electric Scooter Motors

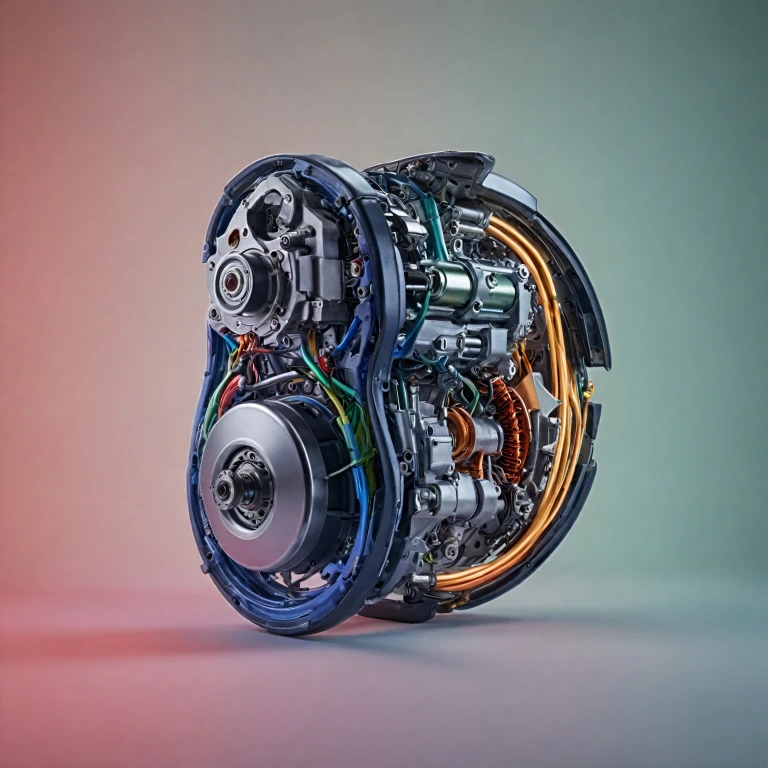

Electric scooters have transformed urban commuting, offering a blend of convenience and eco-friendliness. To understand what drives these marvels, it's essential to delve into the different types of electric scooter motors. Each motor type has distinct characteristics that define the scooter's performance, speed, and overall effectiveness. One prevalent type is the hub motor, which is popular for its compact design. These motors are integrated directly into the wheel, ensuring a space-efficient setup. A hub motor is celebrated for its seamless operation and minimal maintenance requirements compared to chain-driven alternatives. These hub motors often come in various sizes, with the motor inch variants being pivotal elements in customizing the electric scooter’s power and performance. Their appeal is further amplified by the availability of motor kits that allow easy upgrades. Another type of motor is the belt-driven motor, known for offering a smoother ride with enhanced power transfer. This design is often favored for electric scooter models that prioritize performance and acceleration. Belt-driven designs might require more regular upkeep but offer the possibility of higher performance and customizable control. The choice between different motors can significantly impact the price and driving experience of the electric scooter. While electric scooters with hub motors tend to be more budget-friendly and come with free shipping options on occasion, the high-performance scooters incorporate advanced motor technologies, which may come at a price premium. Beyond these categories, emerging tech advancements in motor units continue to drive innovation. Up-and-coming technology trends promise to deliver motors with better speed, lower unit price, and increased power output without compromising on size, thus revolutionizing the electric scooter landscape. For those curious about how these diverse motors correlate with the speed of electric scooters, exploring these variations further can shed light on the intricate dynamics behind your daily ride.How Electric Scooter Motors Work

Delving into the Complex Mechanics of Electric Scooter Motors

Understanding how electric scooter motors work can significantly enhance your comprehension of their importance in both performance and efficiency. These motors are the powerhouse of electric scooters, transforming electrical energy from the battery into the mechanical energy needed to drive the scooter forward. One critical component worth noting is the electric scooter engine, which plays a vital role in dictating the riding experience. The process begins with the battery supplying power, which is then transferred to the motor through a controller. The controller's role is to modulate the current and voltage to control the speed and acceleration. This aspect is crucial as it ensures the scooter performs optimally under various conditions and load. There are different types of motors for scooters, namely hub motors and chain-driven motors, each with its benefits and drawbacks. Hub motors, often integrated within the wheel, offer a compact design and quieter operation. They are typically lighter and require less maintenance, owing to fewer moving parts. Meanwhile, chain-driven motors provide higher torque, which is beneficial when tackling steep inclines or rough terrains. Maintaining high performance involves understanding the interplay between the motor's power output, the wheel's size, and the scooter's overall weight. Additionally, factors like motor efficiency and the ability to maintain a regular speed even under load play a significant role in the scooter's functionality. In essence, the more you understand the workings of scooter motors, including aspects like the controller's role, battery capacity, and wheel size, the better equipped you are to make informed decisions about regular maintenance, parts replacement, and even considering a sale price for potential upgrades or replacements in your electric scooter journey.Performance Factors of Electric Scooter Motors

The Influence of Performance on the Riding Experience

When delving into the performance of electric scooter motors, it's crucial to understand the various factors that play a role in determining how well your electric scooter will operate. The performance of these motors is influenced not only by the motor itself but also by several associated components and specifications.

Motor Power and Efficiency

The power of a motor electric plays a significant role in determining the overall performance of an electric scooter. Higher wattage in motors generally translates to faster speeds and better torque, which is critical for traversing inclines or carrying heavier loads. Hub motors are particularly popular in the scooter industry for their compact design and efficient power delivery. The balance between power and battery efficiency is crucial, as greater power often leads to quicker battery depletion.

Wheel Size and Torque

Wheel size, often measured in inches, has a direct impact on the motor's ability to provide smooth rides. Larger wheels can generally deliver better overall performance by handling rough terrains more effectively. They also contribute to improved torque and speed, essential for the optimal riding experience. A motor inch of the right size ensures that power is utilized efficiently, contributing to better control and smoother rides.

Battery and Controller Interaction

The battery and motor controller play pivotal roles in determining performance. A well-matched battery and controller can optimize the flow of power, ensuring that the electric scooter can deliver peak performance without unnecessary energy waste. Batteries with high capacity can support powerful motors, allowing for longer distances without a recharge. It's important to choose components that complement each other to ensure consistent and reliable performance.

For heavier riders or those looking to understand how different factors come into play, exploring choosing the right electric scooter for heavier riders might offer additional insights. The riding experience is greatly influenced by these performance factors, and understanding them can help in making informed purchasing decisions.

Maintenance Tips for Electric Scooter Motors

Optimizing Efficiency: Basic Care and Routine Checks

Proper maintenance of your electric scooter motor is essential to keep your ride in top condition and extend its lifespan. Whether you own a high-performance electric motorcycle or a standard scooter, regular checks can make a significant difference. Here's how to maintain peak performance:- Inspecting the Battery: The battery is the powerhouse of your scooter. Regularly check for corrosion or leakage, and ensure that it is charged according to the manufacturer's guidelines. A well-maintained battery translates into better motor power and efficiency.

- Checking Connections: Ensure all electrical connections are secure. Loose cables can affect the motor's performance negatively by hindering electrical flow.

- Cleaning and Lubrication: Dust and debris accumulation can impact the motor's efficiency. Clean your scooter regularly, focusing on the hub motor and wheel area. Lubricate moving parts as needed to reduce friction and wear.

- Tire Inspection: Keep an eye on tire condition and pressure. Under or over-inflated tires can lead to decreased speed and increased strain on the motor, affecting the scooter's overall performance.

- Reviewing the Controller: The scooter's controller regulates power and speed. Periodically review its settings to ensure they align with your performance needs.

Common Issues with Electric Scooter Motors

Identifying and Addressing Common Problems in Electric Scooter Motors

Electric scooters, with their efficient electric motors and growing popularity, occasionally face certain issues that can affect their performance and longevity. Understanding some common problems and solutions can not only save on repair costs but also enhance the overall experience of your electric scooter.- Battery-Related Issues

- Hub Motor Malfunctions

- Controller Failure

- Wear and Tear of Parts

- Water Damage

Future Trends in Electric Scooter Motor Technology

Trends Shaping the Future of Electric Scooter Motors

The electric scooter market is evolving rapidly, tackling both consumer demands for high-performance and environmentally conscious design. As technology progresses, we see changes impacting both the efficiency and functionality of electric scooter motors. Here are key trends that could shape their future:- Enhanced Motor Efficiency: Innovations are aiming at squeezing more power from compact motors without increasing their regular price. There's a strong focus on boosting power output while reducing energy consumption, ultimately leading to electric scooters with superior range.

- Integration of Hub Motors: Hub motors, directly fitted into the wheel of a scooter, simplify design and maintenance. Improvements in hub motor technology will likely make scooters lighter and more efficient, while the integration offers better performance and a more streamlined look.

- Smart Controllers: The use of advanced, intelligent controller systems enables better power regulation, extending battery life and optimizing how energy flows through the entire scooter motor system. This can enhance speed and energy efficiency.

- Increasing Popularity of Electric Motorcycles: There's a blurring line between electric scooters and electric motorcycles, with consumers seeking performance akin to motorcycles in an easier-to-manage scooter format. This blend prompts manufacturers to innovate in motor capacity and price sale models.

- Open Software Platforms: With the growing sophistication of scooter parts, suppliers are leaning toward open software platforms allowing users to tweak system settings according to their needs. This adaptability helps in fine-tuning motor performance according to user preferences or terrain demands.

- Focus on Sustainability: As consumers increasingly demand environmentally friendly options, manufacturers are under pressure to ensure the production and shipping processes are eco-friendly while maintaining free shipping benefits.